Let us take you along the process

We embrace emerging technologies that allow us to guarantee fast,

accurate, and stylish results.

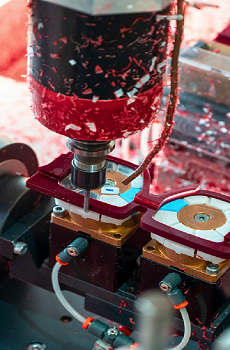

We utilize state-of-the-art tools like AutoCAD

and 3D modeling. These industrial design illustrations

provide a tangible

confirmation of the production process, ensuring that the eyewear

is

meticulously crafted with precision and finesse.

We use acetate sheets produced by

Mazzucchelli, a worldwide leader in

the manufacture and distribution of

cellulose acetate products for the

eyewear industry.

Acetate - also known as cellulose

acetate or zylonite - is made from

wood pulp and cotton. Organic powders

are used to apply the colors, and the

acetate sheets are then passed through

rollers multiple times to achieve the

desired thickness.

Whenever an acetate sheet is produced,

technicians preserve a sample for future

reference in order to replicate the pattern.

The entire process involves repeating these steps

over several weeks, in order to achieve the desired

color patterns

We have our own, unique polishing method. We have adopted the old school traditional Italian production methods of luxury eyewear and we changed a few production steps, adding new materials derived from Greek nature, enhancing the quality of the final outcome. It takes 72 different phases of production to have a final pair of sunglasses with more than 30 artisans to collaborate in this creation.

We consistently deliver remarkable eyewear that exudes class and refinement, by fusing new technologies with classic design values.